Accelerating the future

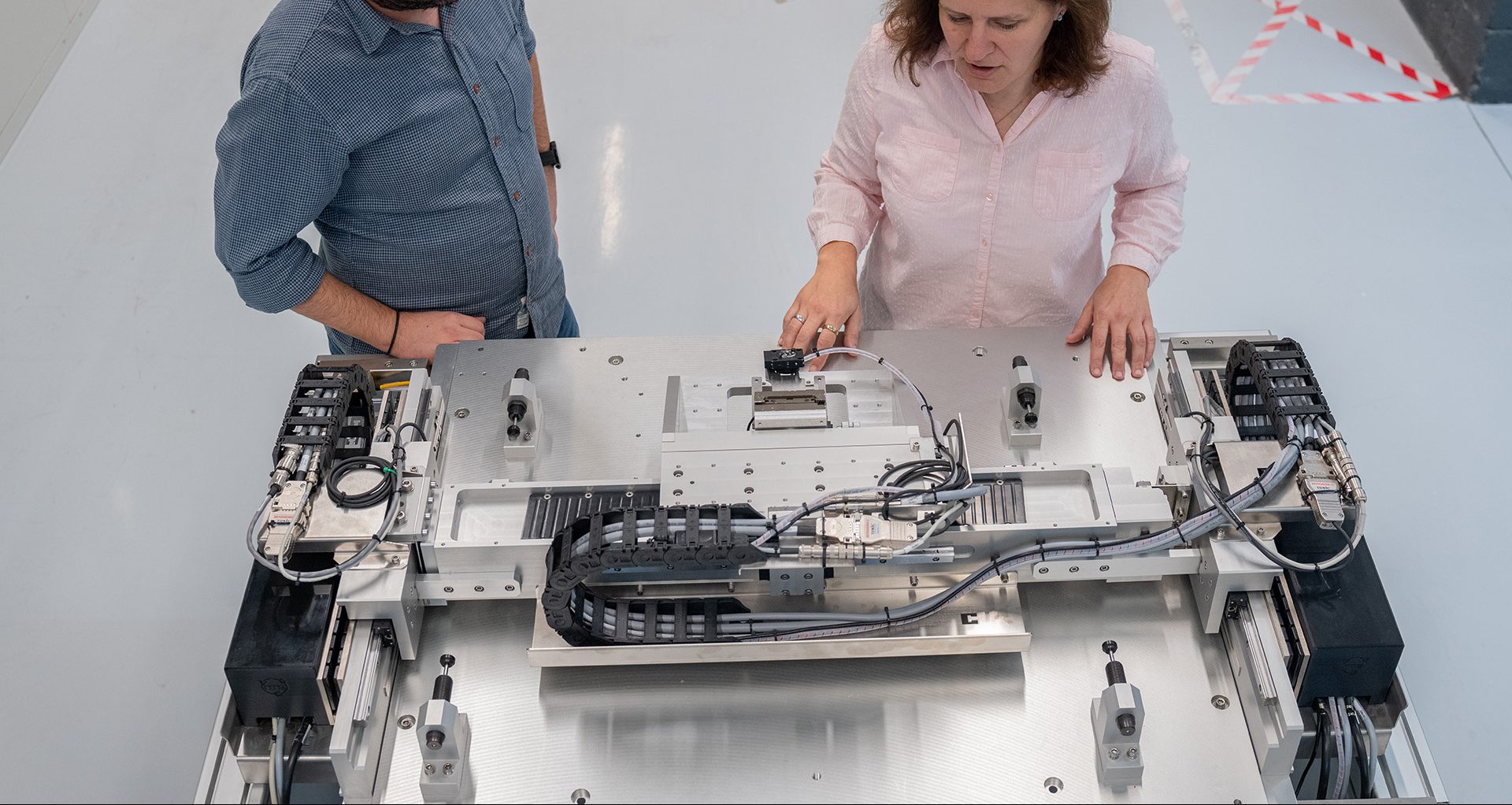

First-tier contract manufacturer of (opto-) mechatronic systems

Quick links

Technologies

With our extensive technical knowhow, we provide all solutions for large, high-tech machine manufacturers (OEMs), under one roof.

Realization

Next to our technical expertise, we possess the skills and facilities to realize the best fitting solution for our customers.

Who we are

Accelerating the Future Together

As a first-tier contract manufacturer in (opto-) mechatronic systems and mechanical modules, we take the technological development of our OEM customers to the next level.

Focus areas

Semiconductor

The semiconductor market is innovating rapidly. In front-end and back-end semiconductor technology, we maximize value.

Semiconductor

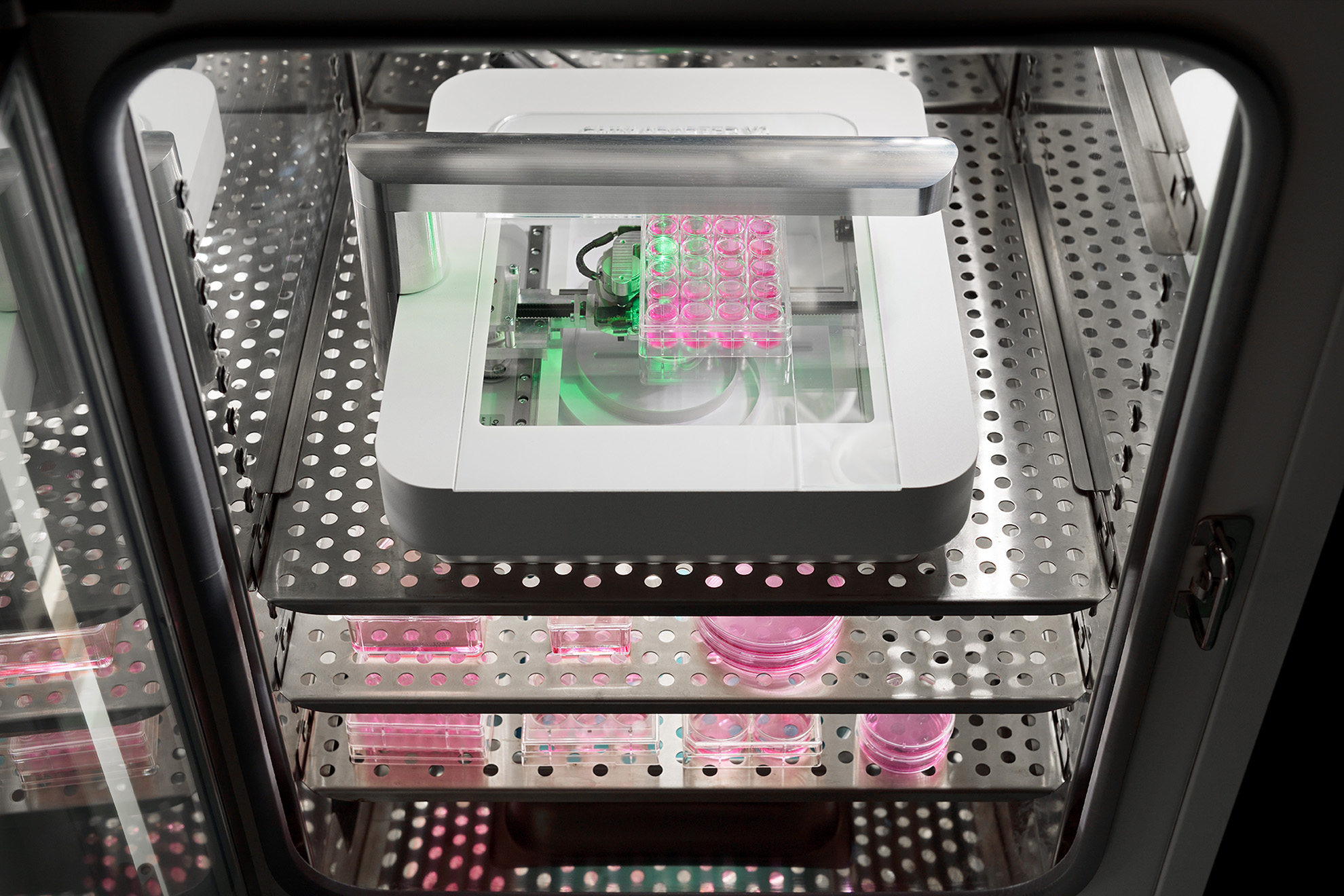

Analytical

Whether we’re talking analytical microscopes, mass spectroscopy or flow cytometry – the analytical market is all about innovation.

Analytical Market

Health & Industry

The high quality and precision requirements of our core markets also apply to our solutions for medical and industrial sector.

Health & Industry MarketCareers

We always have Room for Talent and Ambition

The career opportunities within the worldwide NTS family are infinite. You’ll find a wide range of disciplines and jobs at NTS.

NTS in Numbers

0

Approach

0

Countries

0

Years of Experience

0

Million revenue

0

Colleagues